DEP’s Simulation Technology Improves Quality in Manufacturing Industry

Published on May 31, 2021

Chennai : In the current highly competitive business environment, the manufacturing industry is facing constant challenges of producing innovative products at shortened time-to-market. On the contemporary path, technology transformation pushes past the conventional manufacturing process, innovatively and promptly. The need for efficiency in the manufacturing industry has never been greater and successful companies need to ensure that the costs associated with time, equipment and other investments are being considered and optimized.

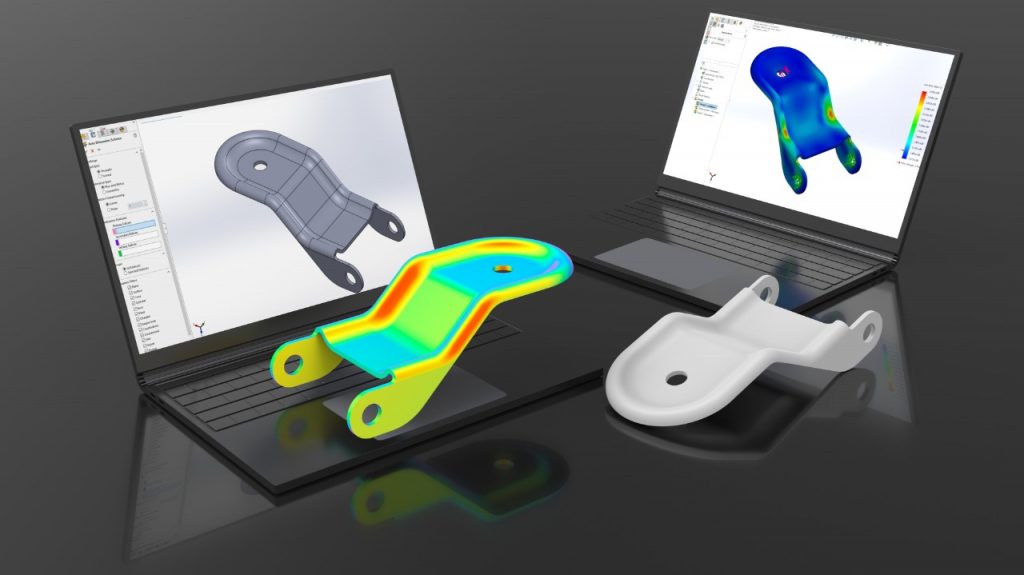

Detroit Engineered Products (DEP) proprietary product development platform MeshWorks, is a unique & powerful simulation tool that enables manufacturing organizations to increase throughput, identify process bottlenecks and inefficiencies within the production line. In manufacturing, simulation technology significantly impacts many decisions like project complexities and challenges. With MeshWork’s simulation-driven-design technology opportunities to change the manufacturing processes are made available at the early stages of design & development. This in turn leads to increased structural efficiencies achieved by minimizing the weight of components and assemblies, ultimately resulting in optimized products.

As the use of simulation tools for enhancing product performance increases, there are simultaneous efforts focused on the democratization of simulation, and boosting advanced simulation tactics using multi-disciplinary optimization (MDO), Artificial intelligence (AI), Machine Learning (ML), etc. Given MeshWorks’ advancement as an easier and more accessible simulation tool even for non-experts, it is now the choice of the manufacturing organization as an insight provider for a better design and process.

Radha Krishnan, Founder & President, Detroit Engineered Products (DEP) said, “We believe in a stronger integration of DEPMeshWork’s simulation techniques into the design environment, for earlier detection of design improvements in a cost-effective way. We provide guided simulation workflows in MeshWorks for repeatable CAE process applications that can improve efficiency and decrease the overall time needed for simulation-based design, as well as the need of a trained professional to operate it.”

DEPMeshWorks’ manufacturing simulation functions are designed to help improve the life of tooling and reduces manufacturing defects. For manufacturers, it gives real-time inputs to reduce scrap during manufacturing by way of design suggestions like shape effects, structural performances, connection types, joint strength, and joining sequence. Also, there are part level and assembly level assistance programs for manufacturing processes that are applicable based on product development requirements.